-

Pneumatic Ball Valve

-

Pneumatic Butterfly Valve

-

High Pressure Ball Valve

-

Ventilation Butterfly Valve

-

Damper Valve

-

FB Ball Valve

-

High Temp Ball Valve

-

Industrial Butterfly Valve

-

High Temperature Pneumatic Valve

-

High Temperature Globe Valve

-

Vacuum Ball Valve

-

Special Purpose Valves

-

Threeway Valve

-

RTO Valve

-

Pneumatic Actuator

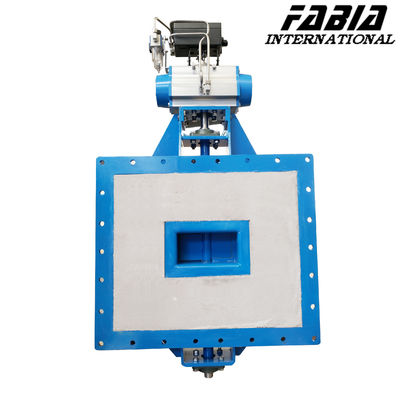

High Pressure High Temperature Flue Gas Butterfly Valve Carbon Steel Pneumatic Air Valve

| Place of Origin | China |

|---|---|

| Brand Name | FABIA |

| Certification | ISO9001,CE,CCS,DNV |

| Model Number | 1/8 inch ~ 36 inch |

| Minimum Order Quantity | 1 set |

| Price | Negotiable |

| Packaging Details | Cartons/Wooden cases |

| Delivery Time | 15-30 work days |

| Payment Terms | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability | 100-1000 set per week |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | High Temperature Flue Gas Butterfly Valve | Type | Damper Valve |

|---|---|---|---|

| Actuator | Pneumatic | Material | Carbon Steel |

| Connection | Flange | Control Mode | Pneumatic |

| Application | Petroleum, Chemical, Power, Etc. | Pressure | 20MPa |

| Size | Support Customization | Temperature | 1000℃ |

High Pressure High Temperature Flue Gas Butterfly Valve Carbon Steel Pneumatic Air Valve

1. Description:

Working principle of high temperature butterfly valve:

The high temperature flue gas butterfly valve body is welded by steel plate and forging flange.

The stem is an integral forging structure, supported by an external bearing seat and driven by a two-end pin connection to turn the disc.

The two semi-round seats are staggered before and after, and are symmetrically distributed and combined with the valve disc.

The symmetrical and streamlined structure of the valve disc makes the valve have good flow performance.

The high reliability valve stem packing sealing system is composed of three packing seals, additional sealant and purge secondary auxiliary seals.

Process technology:

High temperature flue gas butterfly valve is used for the flue gas recovery system of the catalytic cracking unit, the normal operating temperature of the device is 680 ℃, the high continuous use temperature is 720 ℃, the high temperature is 800 ℃, and the recycled flue gas medium containing catalyst particles is transported. Due to the strong erosion of the medium on the valve.

In order to prevent the failure of the valve body wall thickness due to erosion and thinning, the large area of hard alloy in the valve body is prone to deformation and cracking, and the surfacing welding is difficult. Because the system temperature is high, the mechanical properties of metal materials decline sharply at high temperatures, and the valve should be selected for high temperature resistance.

2. Specification:

| FABIA Valve Parameter List | ||

| Valve type: | High Pressure High Temperature Flue Gas Butterfly Valve Carbon Steel Pneumatic Air Valve | |

| Size: | 1/8 inch ~ 36 inch | |

| Material: | WCB,GGG40,FCD,SS304,SS304L,SS316,SS316L,ST37(Q235B),SS410 | |

| Connection type: | Butt /Flange Connection | |

| Driving model: | Manual/Worm gear drive/Pneumatic/Electric | |

| Pressure rating: | PN0.1~PN16 | |

| Temperature: | -40℃~1000℃ | |

| Model: | FB-F.......... | |

3. Features:

- Structural design and material. The new structure of medium line plate and short structure plate is welded, which is compact, light and easy to install and maintain. In addition, its structure is simple, no connecting rod, bolts and other internal moving parts, improve the reliability and service life.

- Sealing performance. Both hard and soft seal models provide a reliable two-way seal. The outer circle of the butterfly plate of the hard-sealed butterfly valve adopts a spherical shape, which further enhances the sealing performance and can maintain zero leakage in the high-pressure opening and closing more than 50,000 times.

- Operation and flow characteristics. Easy to operate, 90° turn can be quickly opened or closed. The flow characteristics tend to be straight, and the adjustment performance is good. The butterfly plate can be sprayed with coating according to user requirements, such as nylon or polytetrafluoroethylene, to adapt to different work needs.

- Installation and suitability. Proportional control flue gas butterfly valve is easy to disassemble and maintain. Can be installed in multiple stations, not affected by the flow of media, can be installed in any position.

- These characteristics make the pneumatic proportional control of high temperature flue gas butterfly valve suitable for a variety of industrial fields, especially in the need for precise control and response to harsh working environments (such as high temperature, corrosive media).

- Pneumatic proportional control of high temperature flue gas butterfly valve is widely used in many industries, mainly including:

- Metallurgy: Used in high temperature gas pipelines, as a high temperature gas medium flow adjustment or cutting device.

- Building materials: In the flue gas treatment of industrial furnaces, boilers and other equipment, effectively carry out gas transportation and ventilation.

- Chemical: used as a control valve, it can be used with various actuators to form different performance equipment.

- Power station: Used as a regulating or cut-off device in high-temperature gas pipelines.

- Glass: Used for regulating or cutting off the flow of high temperature gas media.

- Sulfur acid high temperature auxiliary line: and smelting, petrochemical system in the blast furnace air distribution, boiler pipeline as a control valve.

- Petrochemical, cement and other industries: control the flow of high temperature and high pressure gas media.

- These valves are designed to withstand high temperatures, are easy to operate, reliable to use, and can meet the needs of program control and remote control.

![]()